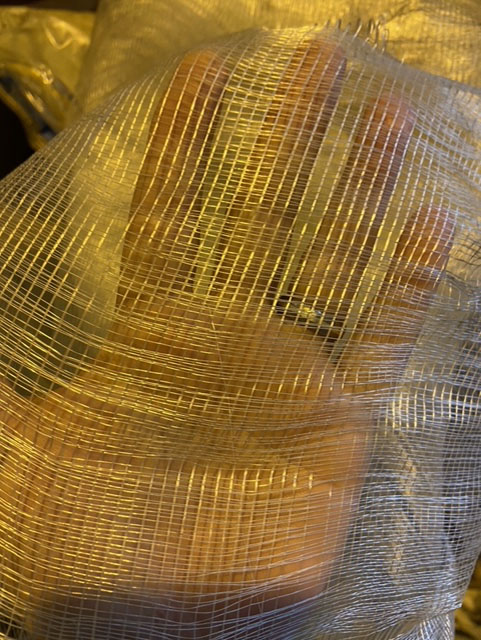

A basic general purpose reinforcement fabric available in a wide range of weights and widths. Extensively used in both hand and machine moulding applications. It has high strength, good wet out and low cost versus more complex fabrics. Lower weight materials are easier to drape and wet out faster than heavier weights. We have a range of woven rovings available in different weight and widths. Please contact us for more information.

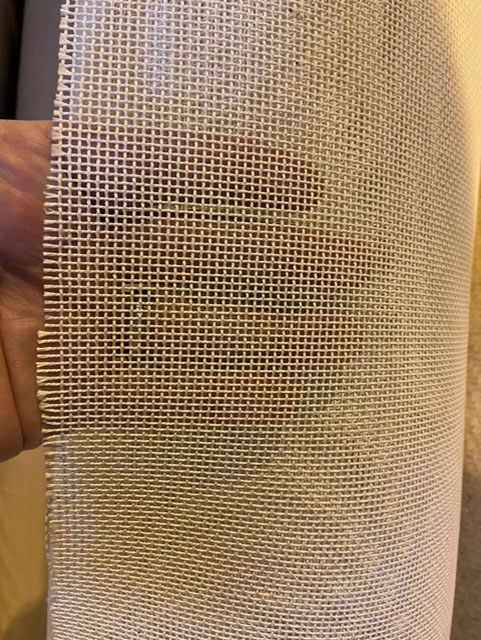

There is a huge array of yarn fabric weights, styles and thicknesses available in the market. Materials can even be custom manufactured for certain applications. Closely woven fabrics are more suited to even and regular surface critical applications. Where you want to have as smooth a surface as possible. More open weave fabrics are more often used in areas requiring extra reinforcement. Their improved drapeability allows them to be accurately positioned in the resin matrix.

Plain weave is the most common fabric. One warp end weaves over one weft and then under the next weft.

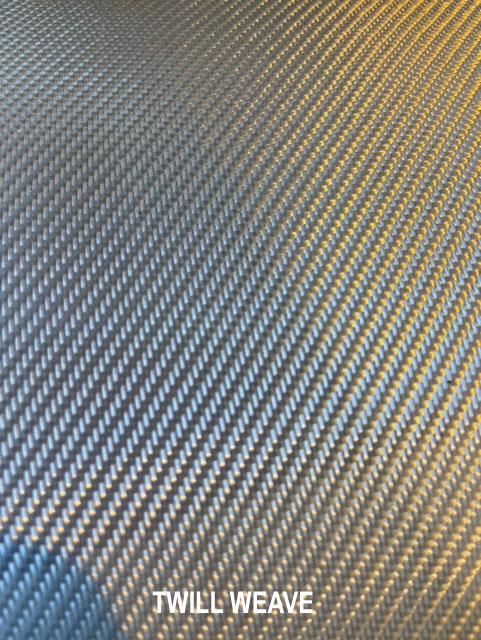

Twill weave is where one warp end weaves over or under two (or more) weft ends. This produces an almost diagonal line in the fabric.

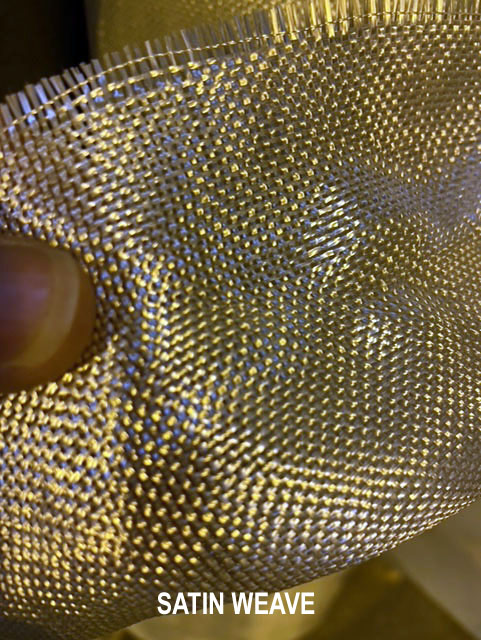

Satin weave is where one warp end weaves over three weft ends. This produces a pliable and more drapeable fabric than plain weave.

Scrims are a very open and loose weave material. They are a very good material for impregnation. Often used with insulation materials, acting as a reinforcement. We have a range of scrims available in different widths and weights.

Combination materials combine a number of different product types together to form a product with a specific set of characteristics. Producing a heavy fabric with good drapeability and excellent strength. We are able to offer the Owens Corning BiPly combination mat, which is ideal for boat hulls, roofing and other high strength requirement applications.